At our company, we approach process engineering by thoroughly analyzing industrial processes to identify areas where efficiencies can be improved, and carbon footprint reduced. We understand the significance of optimizing operations to enhance productivity while minimizing environmental impact.

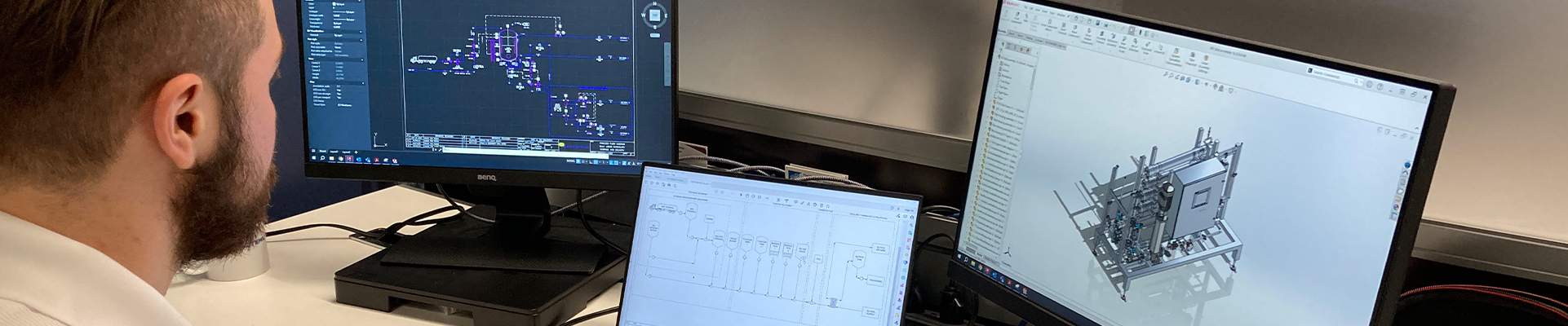

Our first step is to conduct a comprehensive assessment of the existing processes, from raw material sourcing to final product delivery. This allows us to identify energy-intensive steps, waste generation, and potential bottlenecks. We then employ advanced data analysis techniques and simulation tools to model the process and identify areas for improvement.

Why Process Engineering?

With a deep understanding of the process, we collaborate closely with our clients to develop tailored solutions. This may involve implementing energy-efficient technologies, optimizing process parameters, and integrating renewable energy sources. Additionally, we emphasize waste reduction strategies, such as recycling and reusing by products. Throughout the implementation phase, we continuously monitor and evaluate the performance of the updated process, ensuring that the desired efficiencies and environmental targets are met. Regular assessments and data-driven insights help us make necessary adjustments to further optimize operations and reduce carbon emissions. By adopting this approach, we not only enhance operational efficiency and profitability for our clients but also contribute to a sustainable future by reducing their carbon footprint. Our commitment to process engineering goes beyond short-term gains, aiming to create long-lasting positive impacts on both business and the environment.

Process Engineering Services

Our process engineering services for optimization.

- Plant Design Engineering

- Process Optimization

- Advanced Automation Solutions

- Operations Bottleneck and Constraint Analysis

- Technical and Economic Project Evaluation

- Energy and Utilities Optimization

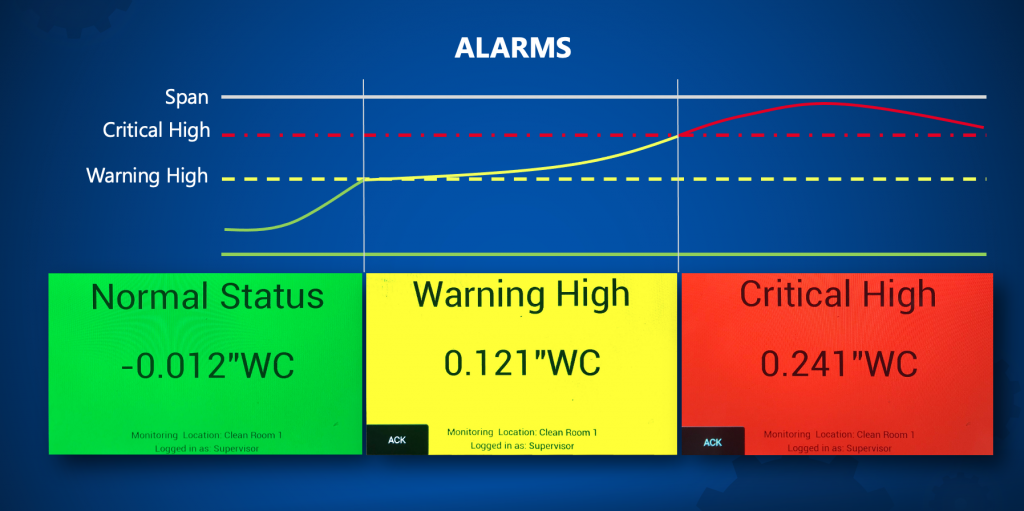

- Process Safety and Hazard Analysis

- Hygienic and Sanitary Design Solutions

- Clean In Place (CIP) Systems Design

- Balance of Plant Design and Optimization

- Construction Field Support and Quality Oversight